Amavavu Wokuhlola Ukumela Okuncane Kancane Kancane

Izici

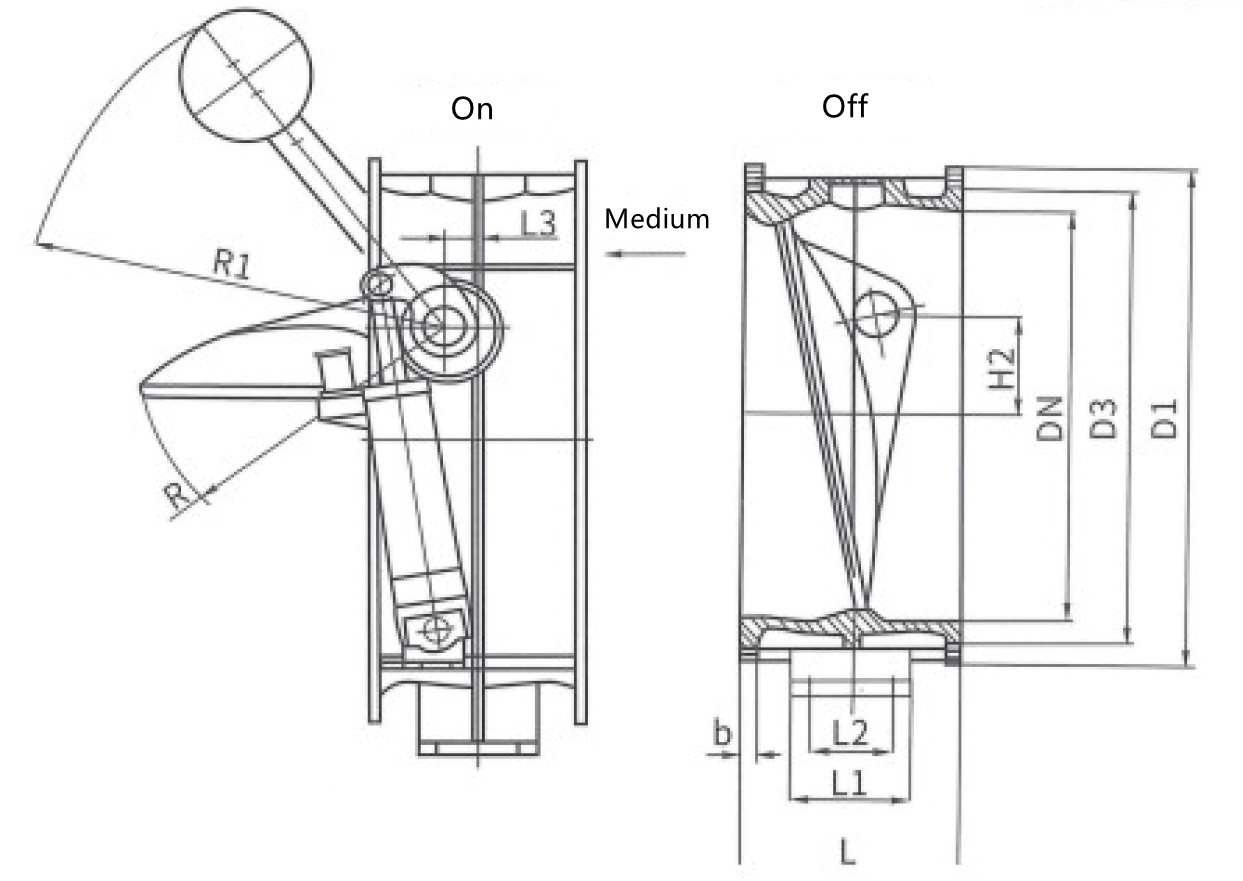

▪ Isikhathi sokushintsha esilungisekayo.

▪ Imodi yokuvala i-valve: vala ngokushesha futhi kancane.

I-Double Offset Disc Disc, ukuvuleka nokuvala kwevalvu okuphusile.

▪ Wonke amapheya ensimbi avalayo kanye namapheya enjoloba angagugi, anempilo ende, ayalungiswa futhi amahhala.

▪ Ezakhiweni zesakhiwo se-valve yesikhala esihlobene nezici zokumelana nokugeleza, izakhi zejometri zinqunywa ngokusebenzisa isimiso se-hydrodynamics ukunciphisa ukumelana nokugeleza nokonga amandla.

▪ Ukusebenza kahle kwe-valve okuvimbela ukwenzeka kwesando samanzi esicekela phansi.

▪ Isiqu sediski/ivalvu singavulwa futhi ivalwe kalula ngaphandle kokuminya.

▪ Ukukhethwa nokumataniswa kwezinto ezihambisana nokushayisana, idizayini yesakhiwo sokuvala kanye nendlela yokufaka ingaqinisekisa ukuthi izingxenye ezijikelezayo ezifana ne-disc/valve stem zingagcina ukusebenza kahle kokuzungeza isikhathi eside.

▪ Ubulula, ukunemba nokuphepha kokusebenza komsebenzisi kanye nokugcina ukusebenza kahle komkhiqizo.

▪ Ubude besakhiwo esifushane nesisindo esincane.

▪ Hlola ingcindezi:

I-Shell Test Pressure 1.5 x PN

I-Seal Test Pressure 1.1 x PN

Ukucaciswa Kwempahla

| Ingxenye | Okubalulekile |

| Umzimba | Insimbi ye-Carbon, i-ductile iron |

| Idiski | WCB |

| Isiqu | 2Kr13 |

| Indandatho yokuvala | Buna-N, EPDM, FKM |

| I-Cylinder Piston Ring | I-alloy cast iron |

| Ezinye izinto ezidingekayo zingaxoxisana. |

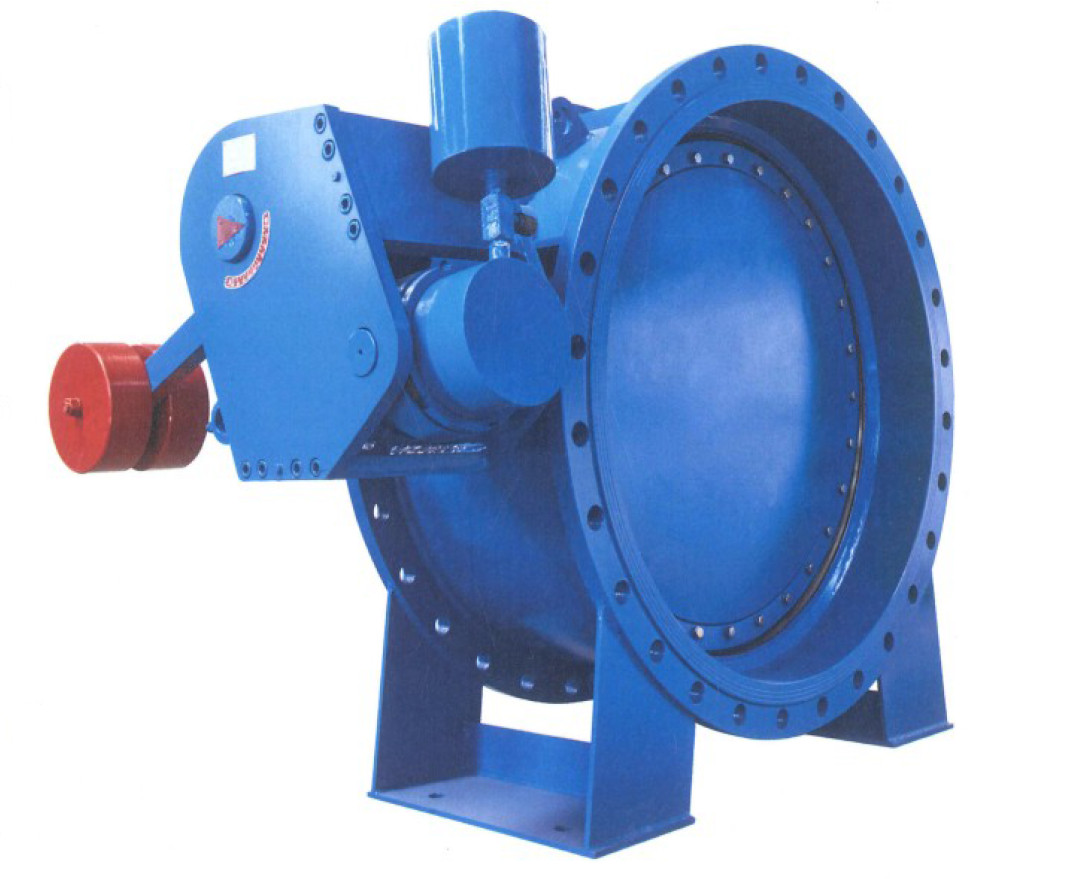

Isakhiwo

Isicelo

▪ Le valve yokuhlola iwuhlobo olusha lomkhiqizo wokonga amandla wesando ongangeni emanzini onesihlalo sevalvu eqondile noma egobekile, idiski eliphindwe kabili le-offset, yonke i-metal sealing pair kanye nepheya ekwazi ukumelana nerabha engagugi, into echichimayo enoketshezi lwesiteshi nokucindezela kukawoyela idivayisi evala kancane, engavala i-valve ngezigaba ezisheshayo / ezihamba kancane.

▪ Ivalvu ingonga amandla ngokusobala lapho isebenza.Uma iphampu ijwayelekile noma iphampu imisiwe uma kwenzeka ukwehluleka kwamandla kungazelelwe, ingavimbela ngokuphumelelayo ukugeleza kwangemuva komzimba wamanzi kanye nokuvela kwesando samanzi esibhubhisayo.

▪ Isetshenziswa kakhulu ku-petrochemical, i-power metallurgy, ukuphakelwa kwamanzi emadolobheni kanye ne-drainage nezinye izinhlelo zamapayipi.